Scientists from the Plastic Innovation Group at University of Delaware, In the United States, they devised a method capable of converting plastic, which is derived from petroleum, into other products of fossil origin as well. You are The results of the experiment have been published in the journal Science Last Wednesday (21).

Lab tests have been able to convert single-use plastic waste, such as plastic bags, yogurt containers, and plastic bottles, into ready-to-use fuel and lubricant fractions that are produced from oil.

This type of process is well suited to the so-called circular economy, which occurs when products that are no longer useful transform into something new and allow the raw materials used to manufacture the item to be reused. In this way, the disposed thing can be used multiple times and enter the cycle of reuse.

As this circular economy advances, the world will need to produce less authentic plastics because we will reuse materials made today in the future, ”said Andrew Danielson, a study author who specializes in chemical engineering at the University of Delaware. Education Foundation.

The research introduces a new catalyst that can accelerate the breakdown of plastics that have a longer recycling process, known as polyolefins. This type of polymer accounts for between 60% and 70% of all plastics produced today.

Additionally, the process requires 50% of the energy used normally to recycle this type of product and does not release carbon dioxide into Atmofesta, a topic that has been widely discussed among authorities around the world.

The new method developed by researchers from the University of North America can also convert mixed plastic waste into other products, all at a temperature of around 250 degrees Celsius, which is considered low to carry out similar operations.

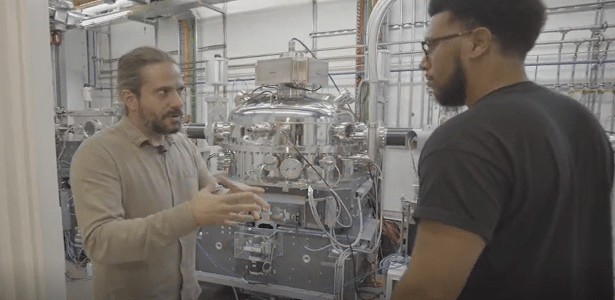

To make the transition, the scientists used a chemical process called hydrocracking to break down solid waste from the plastic into smaller carbon particles. After that, hydrogen molecules were added, which stabilized the material for future use.

A very similar process is performed by oil refineries, however, the newly developed technology converts the material into branched particles, which allows the plastic to be directly transformed into the final product, and thus faster.

Read more: SpaceX’s third space station mission launches

This speed is the result of using different combinations of two catalysts, which are two products that are used to speed up chemical reactions. Scientists at the Plastics Innovation Center used zeolites and mixed metal oxides to improve the process, materials known to form branched molecules and break apart macromolecules, respectively.

“These two stimuli alone work poorly. Their combination works the magic, dissolving the plastic and leaving nothing behind. Plus, these are easy-to-find materials, so we can start thinking quickly about how to use the technology in large-scale operations,” he said. Dionne Flashus, professor of chemical engineering at the University of Delaware and one of the study’s authors.

* Intern R7 Under the direction of Pablo Marquez

“Web geek. Wannabe thinker. Reader. Freelance travel evangelist. Pop culture aficionado. Certified music scholar.”